DOT Certification: Motorcycle Helmets

DOT Certification, often referred to as ‘DOT Approved’, refers to the safety standards applied by law to motorcycle helmets in the United States.

We will take a look at DOT Certification and how it applies to helmets manufactured or imported for the United States domestic market.

KEY TAKEAWAYS

* A DOT approved helmet means that the helmet legally meets the NHTSA standards.

* A DOT approved helmet should reduce death and injuries by protecting the head of the wearer.

* All motorcycle helmets for sale in the United States for use as a motorcycle helmet need to be DOT approved.

* DOT allows for helmet manufacturers to self-certify their helmets.

* Manufacturers face steep fines for applying DOT stickers to inferior helmets.

Disclosure: As an Avantlink and Amazon Associate, we earn from qualifying purchases. Disclosure Statement.

Page Content

What is DOT certification?

A DOT approved motorcycle helmet means that the helmet legally meets the National Highways Traffic Safety Administration’s (NHTSA) set of standards created to ensure helmets provide an acceptable level of protection to the head of the wearer.

DOT being the Department Of Transportation.

FMVSS being the Federal Motor Vehicle Safety Standards.

FMVSS 218 being the safety standard number, within the Code of Federal Regulations, for motorcycle helmets.

A DOT certified helmet (recognized by a DOT sticker on the back of helmet), should therefore meet the expected performance requirements in the event of an accident.

Related Article: What Is A DOT Approved Helmet?

These standards apply to how effective the helmet is at absorbing an impact, deterring an object from penetrating the helmet and how secure the safety strap is to keep the helmet in place.

In short, a DOT approved helmet should serve its purpose to reduce death and injuries by protecting the head of the wearer from impacts during an accident situation.

DOT FMVSS 218

In the words of DOT FMVSS 218, the Scope of the Standard is to establish “minimum performance requirements for helmets designed for use by motorcyclists and other motor vehicle users.”

Manufacturers looking to sell motorcycle helmets in the United States must produce helmets that will pass the DOT testing. If their helmets are manufactured to the appropriate levels of the standard, they can then self-certify and put a DOT sticker on the back of their helmets.

It is then the duty of the Office of Vehicle Safety Compliance to test a number of helmets each year to ensure they are compliant with the DOT standard. If they are found to be not in compliance, they must be withdrawn from sale until proper compliance is achieved.

In such cases the manufacturer can face steep fines of up to $5,000 for each violation with a maximum penalty of $16,050,000 for a series of violations.

Related Article: How To Spot A Fake Motorcycle Helmet

The helmets are tested in 4 different climatic environments to ensure the helmet operates the same in any of the different conditions (the aim being to replicate real-life riding conditions):

- Ambient Conditions: Exposed to a temperature from 61° F to and including 79° F (16° C – 26° C), as well as humidity from 30% to 70% for a minimum of 4 hours.

- Low Temperature: Exposed to a temperature from 5° F to and including 23° F (−15° C to −5° C) for a minimum of 4 hours.

- High Temperature: Exposed to a temperature from 113° F to and including 131° F (45° C to 55° C) for a minimum of 4 hours.

- Water Immersion: Immersed in water at a temperature from 61° F to and including 79° F (16° C to 26° C) for a minimum of 4 hours.

The DOT test then comprises 3 parts:

- Impact Attenuation Test: The helmet is subjected to impacts from a flat anvil and a round anvil at 4 sites on the helmet with 2 impacts per site. There is a ‘test line’ which is around ⅓ of the way down from the top of the helmet and the testers can test any site as long as it is above this line.

The standard specifies precisely the drop height, impact speed, weight of the drop assembly including the weight of the test headform.

The standard further describes the composition of both anvils as well as specifications of the anvil impact face. - Penetration Test: A pointed striker is dropped in a guided free-fall onto various sites on the helmet. There are two penetration strikes which must be at least 3 inches apart.

The standard specifies the height for the free-fall, the precise weight of the striker, and clearly describes the specifications of the point of the striker. - Retention Strap Test: This test is to ensure that the retention strap does not stretch more than 2.54cm (1 inch). The helmet is secured to a stationary test headform to ensure that it does not move during the testing. First, a 50 pound load is applied to the retention system for 30 seconds. Then, an additional 250 pound load is added for a period of 120 seconds. After each test the maximum distance is measured between the extremity of the retention strap and the uppermost point of the helmet.

Related Article: Are Half Shell Helmets Safe?

In addition to the above testing, the helmet must provide sufficient peripheral vision to each side, this is set at 105° from the central point.

DOT Vs Snell

The Snell Memorial Foundation is an independent authority, which, through rigorous testing, aims to improve the standard of protective capability of crash helmets. To obtain Snell approval, manufacturers must first have their helmet DOT approved, only then can they pay to have their helmet tested by Snell.

Helmets subjected to Snell testing are put through much more intense procedures than those that just pass the DOT testing standards.

There are 6 stages to the Snell testing that a helmet needs to pass in order to display a Snell approved sticker:

- Impact test

- Positional Stability test

- Dynamic Retention test

- Chin Bar Rigidity test

- Shell Penetration test

- Faceshield Penetration test

The main differences in the testing is that there are extra tests undertaken, such as: the face shield penetration test; heavier weights are used to test the retention straps performance; the impact test is far more realistic as the helmet is dropped on to a variety of surfaces and the energy the helmet absorbs per impact is measured.

Snell believes that there is a big difference between those helmets passing DOT certification just for legal requirements and helmets that are actually high performing should an accident occur. All motorcycle helmets that are used in racing are Snell approved.

DOT Vs ECE 22:06

The ECE 22:06 standard is the most recognized helmet standard worldwide and also has much more rigorous testing then DOT’s testing procedures.

The most notable difference between the two standards is that ECE 22:05 requires manufacturers to get each and every helmet tested, as opposed to the DOT self-certification model. So, every new model is tested to meet the ECE requirements and are continually tested throughout the production run.

This content was originally published on headsdontbounce.com. If it appears on another website, it is a violation of the copyright owned by headsdontbounce.com.

Further to the conditioning that DOT puts helmets through, the ECE testing requires helmets to be exposed to solvents and ultraviolet lights.

The testing procedures are very similar to that of Snell with some extra checks thrown in for good measure, such as refraction and light transmission levels on the visor.

Frequently Asked Questions:

Q. Do motorcycle helmets have to be DOT approved?

A. All motorcycle helmets for sale in the United States intended for use as a motorcycle helmet need to be DOT approved. Manufacturers need to comply with DOT standards in order to sell their helmets, else they are withdrawn from sale. This is to ensure that all helmets are offering the minimum level of protection to motorcyclists.

Q. How do I know if my helmet is DOT approved?

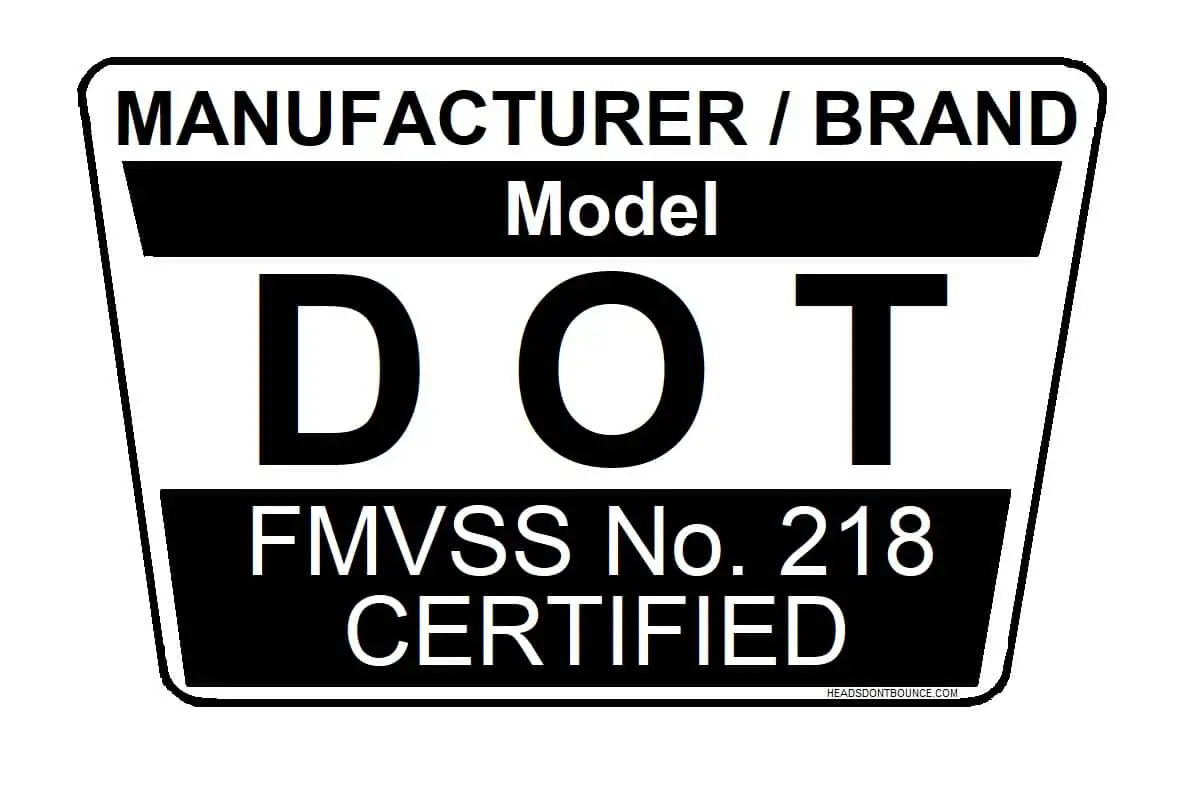

A. As of 2013, FMVSS No: 218 requires all manufacturers to place a label on or inside the helmet, stating the manufacturer and/or brand, model designation, DOT, FMVSS No. 218, CERTIFIED, as per the image below. A helmet that does not meet DOT standards will be unlikely to have such labeling.

There are other things to check such as the thickness of the inner liner, how sturdy the chin strap is and how much the helmet weighs. Please see this brochure from the NHTSA for further detailed information of what to look for.

The safest way to check your helmet is DOT approved is to check everything laid out by the NHTSA; look up the helmet on the manufacturers website and check that it states the helmet as being DOT approved, further to that buy the helmet from a reputable retailer.

Q. Is there a DOT approved helmets list?

A. Yes, there is an online database that will show whether your helmet passed or failed testing. You can access the database at NHTSA free of charge. To search the NHTSA database, click on the link, then follow the directions below:

On the Database Search Type tab, select ‘Equipment’ and ‘FMVSS’.

Then click on the Submit Search tab. So, for example, let’s search for a Shoei Neotech II.

In the FMVSS column, select ‘218’.

In the Brand column, select ‘Shoei’.

In the Model column, select ‘Neotec II’.

Leave the Year column as ‘All Years’, then click on the ‘Submit Choices’ button.

You can see the result at the bottom of the screen. PASS.

If you want, you can click on the Test Report button which will open a new tab with a link to the Compliance Test Report pdf file. If you open that file, you can see the entire test report for the Shoei Neotec II.

Q. Can I remove the DOT sticker from my helmet?

A. You can remove the DOT sticker from your helmet, although you must check the interior sticker is in place as this is the one that will prove the helmet to be DOT approved. The interior label contains the serial number.

For convenience it is better to leave the DOT sticker on the exterior as should you get pulled over and questioned by the police it will likely satisfy them that your helmet is DOT approved.

Q. Are DOT approved helmets legal in the UK?

A. DOT approved helmets are not legal for road use in the UK. Helmets for UK motorcyclists need to meet the ECE 22:05 standards, there may be occasions where helmets are both DOT approved and ECE approved, where manufacturers produce helmets for both the UK/EU and US.

However, it is very important motorcyclists in the UK purchase a model with the ECE certification. For example if a helmet is purchased in the US that is the same model as one sold in the UK but it does not have the ECE sticker, it can be difficult to prove that the helmet does in fact meet the correct standards.

This is not helped by the fact that some manufacturers will produce what seems to be the same helmet, get it DOT approved and on sale in the US; then they may need to make extra adjustments to pass the ECE standards. Therefore, the helmet for sale in the UK is not actually structurally the same as the one that is DOT approved, and as a result may not meet the ECE 22:06 standard.

I hope we have covered the subject of ‘DOT Certification’ to your satisfaction. If you enjoyed this article, feel free to leave a comment or question below. Thanks!

If you liked this post, why not share it with your friends.